|

| January 17, 2017 | Volume 13 Issue 02 |

Software News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

hyperMILL 2024 CAD/CAM software suite

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

Learn more.

Find test data issues faster: AI Anomaly Detector

It can take months of manual engineering time to detect test data abnormalities. Now the task can be performed in a flash. Artificial intelligence software provider Monolith has developed the industry's first AI-powered Anomaly Detector software that can discover a broad range of issues in test data fast -- measurement or sensor errors, user errors, system malfunctions, or incorrect usage of the system during testing. It does this by automating the process of raw test data inspection to look for potential errors or abnormalities across hundreds of test channels.

It can take months of manual engineering time to detect test data abnormalities. Now the task can be performed in a flash. Artificial intelligence software provider Monolith has developed the industry's first AI-powered Anomaly Detector software that can discover a broad range of issues in test data fast -- measurement or sensor errors, user errors, system malfunctions, or incorrect usage of the system during testing. It does this by automating the process of raw test data inspection to look for potential errors or abnormalities across hundreds of test channels.

Learn more.

Loss-free conversion of 3D/CAD data

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

Learn more.

Top 5 reasons for solder joint failure

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Read this informative ANSYS blog.

How a BattleBot was built using Onshape

Learn how RoboGym Robotics, a veteran BattleBots team, said goodbye to Solidworks and took their design game to the next level using Onshape, the cloud-native, all-in-one CAD and PDM solution. RoboGym was able to analyze key components of their Roundhouse BattleBot like its armor and weapon bar, run simulations, collaborate, iterate, and optimize their design to its fullest.

Learn how RoboGym Robotics, a veteran BattleBots team, said goodbye to Solidworks and took their design game to the next level using Onshape, the cloud-native, all-in-one CAD and PDM solution. RoboGym was able to analyze key components of their Roundhouse BattleBot like its armor and weapon bar, run simulations, collaborate, iterate, and optimize their design to its fullest.

Read this informative Onshape blog.

Trick to measuring angles in SOLIDWORKS

Learn from the pros at TriMech how to take angle measurements easily in SOLID-WORKS. TriMech has an entire YouTube channel dedicated to SOLIDWORKS tips, and the company is excellent at training too.

Learn from the pros at TriMech how to take angle measurements easily in SOLID-WORKS. TriMech has an entire YouTube channel dedicated to SOLIDWORKS tips, and the company is excellent at training too.

View the video.

COMSOL Multiphysics Version 6.2 is here

COMSOL Multiphysics Version 6.2 introduces faster solvers for turbulent fluid flow, electric motors, and room acoustics. It also brings data-driven surrogate model functionality for creating multiphysics-based digital twins and building fast and accurate standalone simulation apps. Get the full details of what's new in the latest version.

COMSOL Multiphysics Version 6.2 introduces faster solvers for turbulent fluid flow, electric motors, and room acoustics. It also brings data-driven surrogate model functionality for creating multiphysics-based digital twins and building fast and accurate standalone simulation apps. Get the full details of what's new in the latest version.

Learn more.

17 ways SOLIDWORKS 2024 helps you work faster

SOLIDWORKS 2024 helps designers and engineers work faster than ever. Learn all about improvements to core 3D CAD modeling features, new 3D modeling techniques, and graphical and software performance boosts that will help you get your parts made and your products developed in record time.

SOLIDWORKS 2024 helps designers and engineers work faster than ever. Learn all about improvements to core 3D CAD modeling features, new 3D modeling techniques, and graphical and software performance boosts that will help you get your parts made and your products developed in record time.

View the video.

6 tips to streamline workflow in Mastercam 2024

Mastercam 2024 CAD/CAM software has been intentionally upgraded to make programming fast and easy. It prioritizes streamlining workflow so that the entire machining process -- from design to QC -- is as efficient as possible. Learn how to maximize the benefits of Mastercam 2024, including special toolpaths, easier hole-making operations, wireframe shortcuts, and more.

Mastercam 2024 CAD/CAM software has been intentionally upgraded to make programming fast and easy. It prioritizes streamlining workflow so that the entire machining process -- from design to QC -- is as efficient as possible. Learn how to maximize the benefits of Mastercam 2024, including special toolpaths, easier hole-making operations, wireframe shortcuts, and more.

Read this informative Mastercam blog.

How CT data analysis is helping TE Connectivity reach their goal of end-to-end quality inspection

In a bid to cut their mold and part development process to 25% of the time it took in the past, TE Connectivity has taken ambitious steps to interconnect design and simulation with quality measurement. Learn how the company, in collaboration with PTC (Creo) and Volume Graphics, has worked to ensure as-designed parts match as-manufactured parts as early in the process as possible. An in-depth and illuminating read.

In a bid to cut their mold and part development process to 25% of the time it took in the past, TE Connectivity has taken ambitious steps to interconnect design and simulation with quality measurement. Learn how the company, in collaboration with PTC (Creo) and Volume Graphics, has worked to ensure as-designed parts match as-manufactured parts as early in the process as possible. An in-depth and illuminating read.

Read the full article.

State-of-the-art mesh morphing technology for super optimization: Ansys and RBF Morph join forces

After a long and successful OEM partnership with Ansys, mesh morphing pioneer RBF Morph has two proprietary products featured among the world simulation leader's offerings: Ansys RBF Morph Fluids and Ansys RBF Morph Structures. Thanks to mesh morphing, companies can substantially reduce computational time while performing highly automated design optimization analysis, increasing products' reliability and performance while cutting costs, delivery time, and environmental impact.

After a long and successful OEM partnership with Ansys, mesh morphing pioneer RBF Morph has two proprietary products featured among the world simulation leader's offerings: Ansys RBF Morph Fluids and Ansys RBF Morph Structures. Thanks to mesh morphing, companies can substantially reduce computational time while performing highly automated design optimization analysis, increasing products' reliability and performance while cutting costs, delivery time, and environmental impact.

Read the full article.

Top Tech Tip: Creating drafts with the rib feature in Onshape

Ribs are used to add stiffness and strength to parts without adding excessive weight or increasing wall thickness -- most commonly in molded parts that require a draft angle so the part can release from the mold. See the basics of how this is done in Onshape, which features the power of cloud computing, real-time collaboration tools, and a built-in PDM system -- all for the same price as CAD.

Ribs are used to add stiffness and strength to parts without adding excessive weight or increasing wall thickness -- most commonly in molded parts that require a draft angle so the part can release from the mold. See the basics of how this is done in Onshape, which features the power of cloud computing, real-time collaboration tools, and a built-in PDM system -- all for the same price as CAD.

Learn more.

How to design a spoon with subdivision modeling: SOLIDWORKS xShape

Learn how to design a spoon with SOLIDWORKS xShape, which is found in 3D Sculptor on the 3DEXPERI-ENCE platform. xShape is a next-gen subdivision modeling tool that runs entirely in your browser and takes a freeform approach to creating complex shapes and surfaces. You can design 100% in the cloud or seamlessly integrate your xShape models with your SOLIDWORKS designs. Follow along with this 7-minute tutorial to see what it's all about.

Learn how to design a spoon with SOLIDWORKS xShape, which is found in 3D Sculptor on the 3DEXPERI-ENCE platform. xShape is a next-gen subdivision modeling tool that runs entirely in your browser and takes a freeform approach to creating complex shapes and surfaces. You can design 100% in the cloud or seamlessly integrate your xShape models with your SOLIDWORKS designs. Follow along with this 7-minute tutorial to see what it's all about.

View the video.

What's new in Onshape?

Check out the latest updates to Onshape, the cloud-native product development platform that delivers professional-grade CAD capabilities with next-gen product data management. New features include customizable keyboard shortcuts, better BOM navigation, improved drawing tools, and new Learning Center content. With Onshape, users can innovate quickly while simultaneously or asynchronously collaborating with other stakeholders on any web-connected device.

Check out the latest updates to Onshape, the cloud-native product development platform that delivers professional-grade CAD capabilities with next-gen product data management. New features include customizable keyboard shortcuts, better BOM navigation, improved drawing tools, and new Learning Center content. With Onshape, users can innovate quickly while simultaneously or asynchronously collaborating with other stakeholders on any web-connected device.

View the video.

Open-access learning center for multiphysics modeling

COMSOL, the developer of the COMSOL Multiphysics simulation software, has introduced a new online resource that provides no-cost, open access to modeling and simulation learning material across all areas of physics. Designed with the user in mind, the Learning Center offers a single entry point for users of all skill levels, where courses, articles, and videos present a clear path for learning how to use COMSOL Multiphysics for modeling and simulation.

COMSOL, the developer of the COMSOL Multiphysics simulation software, has introduced a new online resource that provides no-cost, open access to modeling and simulation learning material across all areas of physics. Designed with the user in mind, the Learning Center offers a single entry point for users of all skill levels, where courses, articles, and videos present a clear path for learning how to use COMSOL Multiphysics for modeling and simulation.

Check out the COMSOL Learning Center.

Breakthrough solar cell captures CO2 and sunlight, produces burnable fuel

1,000-fold improved chemistry leads to "artificial leaf" that makes syngas.

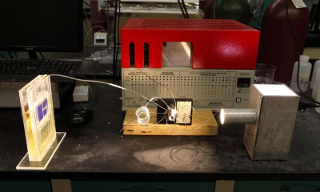

Researchers at the University of Illinois at Chicago have engineered a potentially game-changing solar cell that cheaply and efficiently converts atmospheric carbon dioxide directly into usable hydrocarbon fuel, using only sunlight for energy.

The finding is reported in the July 29 issue of Science and was funded by the National Science Foundation and the U.S. Department of Energy. A provisional patent application has been filed.

Simulated sunlight powers a solar cell that converts atmospheric carbon dioxide directly into syngas. [Credit: University of Illinois at Chicago/Jenny Fontaine]

Unlike conventional solar cells, which convert sunlight into electricity that must be stored in heavy batteries, the new device essentially does the work of plants, converting atmospheric carbon dioxide into fuel, solving two crucial problems at once. A solar farm of such "artificial leaves" could remove significant amounts of carbon from the atmosphere and produce energy-dense fuel efficiently.

"The new solar cell is not photovoltaic -- it's photosynthetic," says Amin Salehi-Khojin, assistant professor of mechanical and industrial engineering at UIC and senior author on the study.

"Instead of producing energy in an unsustainable one-way route from fossil fuels to greenhouse gas, we can now reverse the process and recycle atmospheric carbon into fuel using sunlight," he said.

While plants produce fuel in the form of sugar, the artificial leaf delivers syngas, or synthesis gas, a mixture of hydrogen gas and carbon monoxide. Syngas can be burned directly, or converted into diesel or other hydrocarbon fuels.

The ability to turn CO2 into fuel at a cost comparable to a gallon of gasoline would render fossil fuels obsolete.

Chemical reactions that convert CO2 into burnable forms of carbon are called reduction reactions, the opposite of oxidation or combustion. Engineers have been exploring different catalysts to drive CO2 reduction, but so far such reactions have been inefficient and rely on expensive precious metals such as silver, Salehi-Khojin said.

"What we needed was a new family of chemicals with extraordinary properties," he said.

Salehi-Khojin and his coworkers focused on a family of nano-structured compounds called transition metal dichalcogenides -- or TMDCs -- as catalysts, pairing them with an unconventional ionic liquid as the electrolyte inside a two-compartment, three-electrode electrochemical cell.

The best of several catalysts they studied turned out to be nanoflake tungsten diselenide.

"The new catalyst is more active; more able to break carbon dioxide's chemical bonds," said UIC postdoctoral researcher Mohammad Asadi, first author on the Science paper.

In fact, he said, the new catalyst is 1,000 times faster than noble-metal catalysts -- and about 20 times cheaper.

Other researchers have used TMDC catalysts to produce hydrogen by other means, but not by reduction of CO2. The catalyst couldn't survive the reaction.

"The active sites of the catalyst get poisoned and oxidized," Salehi-Khojin said. The breakthrough, he said, was to use an ionic fluid called ethyl-methyl-imidazolium tetrafluoroborate, mixed 50-50 with water.

"The combination of water and the ionic liquid makes a co-catalyst that preserves the catalyst's active sites under the harsh reduction reaction conditions," Salehi-Khojin said.

The UIC artificial leaf consists of two silicon triple-junction photovoltaic cells of 18 cm2 to harvest light; the tungsten diselenide and ionic liquid co-catalyst system on the cathode side; and cobalt oxide in potassium phosphate electrolyte on the anode side.

When light of 100 watts per square meter -- about the average intensity reaching the Earth's surface -- energizes the cell, hydrogen and carbon monoxide gas bubble up from the cathode, while free oxygen and hydrogen ions are produced at the anode.

"The hydrogen ions diffuse through a membrane to the cathode side, to participate in the carbon dioxide reduction reaction," said Asadi.

The technology should be adaptable not only to large-scale use, like solar farms, but also to small-scale applications, Salehi-Khojin said. In the future, he said, it may prove useful on Mars, where the atmosphere is mostly carbon dioxide, if the planet is also found to have water.

"Nanostructured transition metal dichalcogenide electrocatalysts for CO2 reduction in ionic liquid" is online at http://www.eurekalert.org/jrnls/sci/ or by contacting scipak@aaas.org.

Co-authors with Asadi and Salehi-Khojin are Kibum Kim, Aditya Venkata Addepalli, Pedram Abbasi, Poya Yasaei, Amirhossein Behranginia, Bijandra Kumar and Jeremiah Abiade of UIC's mechanical and industrial engineering department, who performed the electrochemical experiments and prepared the catalyst under NSF contract CBET-1512647; Robert F. Klie and Patrick Phillips of UIC's physics department, who performed electron microscopy and spectroscopy experiments; Larry A. Curtiss, Cong Liu and Peter Zapol of Argonne National Laboratory, who did Density Functional Theory calculations under DOE contract DE-ACO206CH11357; Richard Haasch of the University of Illinois at Urbana-Champaign, who did ultraviolet photoelectron spectroscopy; and Josť M. Cerrato of the University of New Mexico, who did elemental analysis.

Source: University of Illinois at Chicago

Published August 2016

Rate this article

View our terms of use and privacy policy